Designer:

Max Braendli / Switzerland (* 31.03.1924 - † 15.06.2009)

About the designer Max Braendli here

About the aircraft

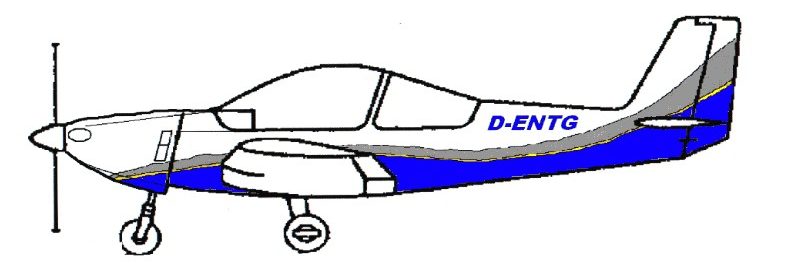

Light-weight-aircraft, 2 seats (side by side), composite-construction (lumber, Styrofoam, glass - fiber and epoxy). Low-wing monoplane with quick removable Wings and retractable nose-wheel-landing-gear. The Flap movement is transferred to the aileron in a reduced rate. Stabilator with anti-servo-flap. Nose-wheel-steering and a shock-absorber (rubber) for the nose-landing-gear.

Main-landing-gear made of strands on a lumber-core, hydraulic-brakes simultaneously applied by lever. Full-sight canopy slides opens in fwd direction. Rudder is cable-controlled, stabilator- and aileron by push rods.

| Vergleich der S/N 001 ( A - 65 ) mit einer 100 PS ( 912 S) und 600 kg MTOW Cherry |  |  |

|---|---|---|

| Cherry Bx-2 | Leistungsdaten HB-YBX (A65 Motor) | Leistungsdaten OE-CRM (mit Rotax 912 S) |

| Spannweite | 7 m | 7 m |

| Länge | 5,23 m | 5,25 m |

| Höhe | 2,03 m | 2,04 m |

| Breite (Cockpit) | 1 m innen (1,1 m außen) | 1 m innen (1,1 m außen) |

| Breite demontiert | 1,96 m | 1,96 m |

| Räder | 3 Stk. 4” x 4” (300x100 mm) | 3 Stk. 4” x 4” (300x100 mm) |

| Rüstgewicht | 315 kg | 373 kg |

| Benzin | 82 L | 105 L |

| Zuladung | 178 kg | 227 kg |

| Abfluggewicht (MTOW) | 550 kg | 600 kg |

| Lastvielfache | Normalkategorie + 3,8 / - 1,9 | Normalkategorie + 3,8 / - 1,9 |

| Motor | Continental A65 | Rotax 912 S |

| Leistung | 41,81 KW (65 PS) @ 2300 rpm | 73,6 KW (100 PS) @ 5800 rpm (max. 5 min) |

| Verbrauch | 13 - 14 l/h -Reise- | 16 - 18 l/h -Reise- |

| V-Reise (2-sitzig) | ca. 200 Km/h (108 kts) | 127 kts (235 km/h @ 18 L/h) 120 kts (@ 16 L/h) |

| Ausfliegbar | 80 Liter | 103 Liter |

| Aktionsradius | 80/14 = 5,7 h mit 220 km/h = 1254 km | 103/18 = 5,6 h @ 127 kts = 807 NM (1494 km) |

| Streckenverbrauch | ca. 7 Liter / 100 km | ca. 7,6 Liter / 100 km |

| V NE | 275 km/h (171 mph oder 149 kt) | 275 km/h (171 mph oder 149 kt) |

| Bestes Steigen (bei Vollast) | 2,6 m/sek (512 ft/min) auf 3000 ft | 1000 ft/min @ MSL |

| Bestes Steigen (solo) | 3,7 m/sek (728 ft/min) auf 3000 ft | 1200 ft/min @ MSL |

| Rollstrecke (bei Vollast) Hartbelag ( Gras) | Start: 290 (380) m Landung: 150 (150) m | Start: 236 m (460 über 15m) Landung: 210 (200) m |

| Lärmpegel | 63 db | 64 db |

Constructional guideline

The load-assumptions, speed-rating as well as equipment were taken from the American

FAR 23 which is also valid in Switzerland. Nevertheless the aircraft remains an “ Experimental ”. A Good aerodynamic was chosen to save Performance, along with economy and low noise emission. Dimensions were kept compact rather than increasing wing aspect ratio for even better aerodynamics. The construction was based on own manufacturing-facilities (welding and painting outside).

Hangar/transportation

Permanent hangar-space is not necessary for the aircraft.

For transportation both stabilizer-halves are removable and can be stowed in the Cockpit.

Then the ”Cherry” will be towed on a simple trailer and fixed. By pulling a bolt the Wings

(30 Kg) can be removed and fixed on the trailer beside the fuselage.

Disassembling and loading take approximately 15 minutes. Same applies for unloading and assembling were all necessary connections are made automatically. The weight of the loaded trailer is about 600 kg.

Building/steps

In order to save limited space with fuselage and wings, small parts and assembly - units should be manufactured at first.

Main-stages of manufacturing:

- Material-procuring (bit by bit is OK)

- Mounts, fittings, wood-ledges, spars

- Stabilizers and vertical-fin

- Main spars

>>> Inspection by examiner <<<

- Pre-assembling of main-landing-gear

- Wings and flaps (including lamination)

- Fuselage-side-walls

- Fuselage-assembly-cradle

- Assembling of fuselage (excluding tank and aft-upper-deck)

- Installation of mean-spar into the fuselage

>>> Load-test and inspection by examiner <<<

- Landing-gear installation

- Installation of controls

- Attaching tail-Unit

- engine-installation

- Fuel-tank-manufacturing and installation

- Aft-upper-deck

- Canopy-frame

- Cowling

- Surface, priming, painting

- Final-assembly, instruments, electric-system

>>> Final inspection by examiner, weigh, 1st run <<<

Homebuilders requirements

The aircraft is not built in a primitive manner and requires anywhere from good up to advanced craftsmanship. The project requires about 4000 hours. Even if the prototype swallowed just 10 000 SFr till it’s 1st flight (including engine and instruments) it is recommended to assign more. During the construction period, which takes a few years, you can easily do without traveling or other expensive activities and thus save quiet the amount of money needed for this project.

Prior to your decision - consider the following:

- Stability of the living-conditions

- Partner’s way of living

- Theoretical and practical abilities

- Flight training

- Perseverance, health

- Workshop: Size, distance to residence, access, heating, ventilation, water

- Tools, machinery

- Concerns of neighborhood (noise, smell)

- Finances for building and future flying

- Aircraft - sheltering

But the most important preconditions are spirit of enterprise, self-confidence and good friends.